cremedemonthe

Well-Known Member

I have seen lots of so called "rolled" leatherwork on internet auctions and websites recently which is not rolled work.

For anyone who is thinking of buying a piece of rolled work whether a bridle or a dog lead/collar here are a few pointers to look out for.

IF you are happy with cheap imitations then fine, this article won't concern you, if you want the real thing read on.

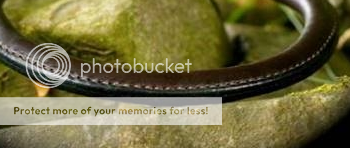

Firstly, proper rolled work involves splitting the leather thickness down, adding a central round core and "rolling" the leather round to give it the shape. Then it should be hand stitched down one side and then finally worked in a rounding block to turn the ends of the leather back over the stitching to hide it. . There's a LOT of work involved to make rolled leatherwork. When finished and smoothed over with a bone and stain, you'll see the edges of the leather but you won't see the stitches, this is proper top quality rolled work.

Most of the rolled work I am seeing you can see the stitching and by looking at the stitching I can tell it's simply run through on a machine, the stitches don't last as long as hand stitched.

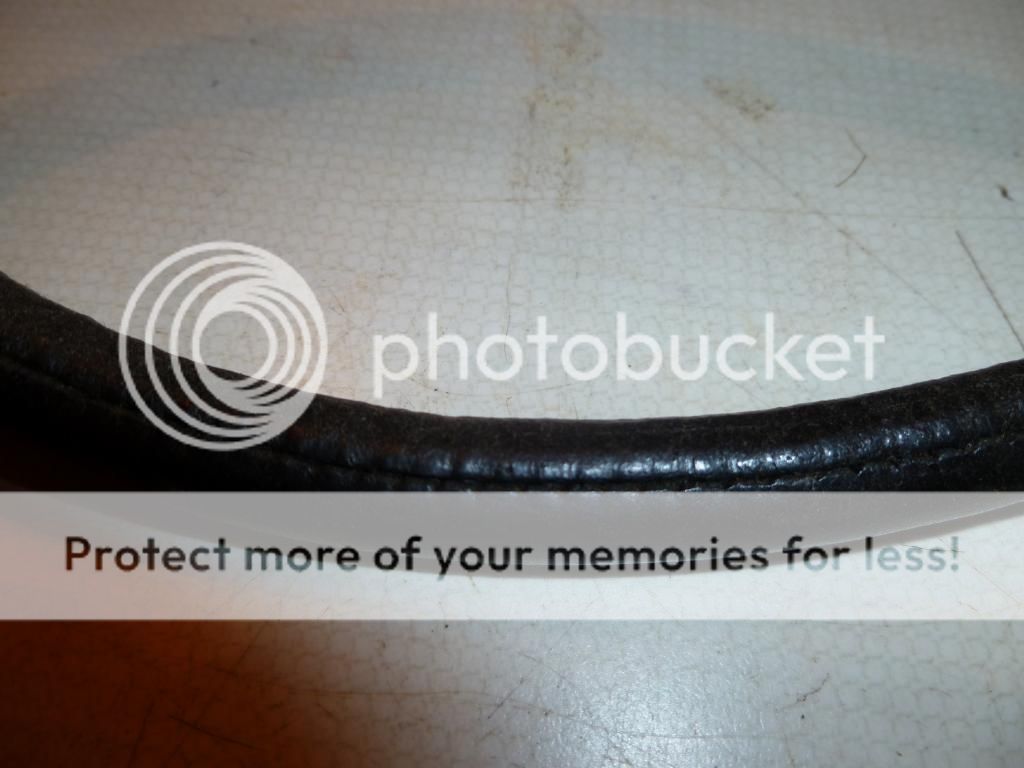

I'm also seeing lots of round leather belting which are lengths of leather bonded together and shaped into a round form.We use it for belts on old treadle sewing machines, some time ago people started using it to make dog leads/collars even bridles but it stretches like mad. I have made a slip lead out of it for my Lurcher, it's cheaper but not as good or as strong as rolled work. The round leather belting will always break before proper rolled work.

Proper rolled work costs much more than round leather belting because of the amount of labour involved so prices should give you a clue, cheap rolled work that you can see the stitching is probably machined or if it is hand stitched it's done by someone who doesn't know how to make rolled work properly, the stitches SHOULD not be seen as the leather turned over them protects them against wear and is an important part of the rolled work manufacture.

Round leather belting is cheaper as you simply buy a roll of it and cut off the length you need to make the item.

The turns on this belting (as in "turn" of leather round fitting such as ring or a buckle) are it's main weak point, even whipped and bound will not be as strong as proper rolled work.

Next time you go to buy any rolled leatherwork and you really WANT rolled work, have a good look at it first, don't simply ask the sellers how it was manufactured, they don't seem to know as I have asked a few.

Hope you can make sense of what I am trying to explain to you.

For anyone who is thinking of buying a piece of rolled work whether a bridle or a dog lead/collar here are a few pointers to look out for.

IF you are happy with cheap imitations then fine, this article won't concern you, if you want the real thing read on.

Firstly, proper rolled work involves splitting the leather thickness down, adding a central round core and "rolling" the leather round to give it the shape. Then it should be hand stitched down one side and then finally worked in a rounding block to turn the ends of the leather back over the stitching to hide it. . There's a LOT of work involved to make rolled leatherwork. When finished and smoothed over with a bone and stain, you'll see the edges of the leather but you won't see the stitches, this is proper top quality rolled work.

Most of the rolled work I am seeing you can see the stitching and by looking at the stitching I can tell it's simply run through on a machine, the stitches don't last as long as hand stitched.

I'm also seeing lots of round leather belting which are lengths of leather bonded together and shaped into a round form.We use it for belts on old treadle sewing machines, some time ago people started using it to make dog leads/collars even bridles but it stretches like mad. I have made a slip lead out of it for my Lurcher, it's cheaper but not as good or as strong as rolled work. The round leather belting will always break before proper rolled work.

Proper rolled work costs much more than round leather belting because of the amount of labour involved so prices should give you a clue, cheap rolled work that you can see the stitching is probably machined or if it is hand stitched it's done by someone who doesn't know how to make rolled work properly, the stitches SHOULD not be seen as the leather turned over them protects them against wear and is an important part of the rolled work manufacture.

Round leather belting is cheaper as you simply buy a roll of it and cut off the length you need to make the item.

The turns on this belting (as in "turn" of leather round fitting such as ring or a buckle) are it's main weak point, even whipped and bound will not be as strong as proper rolled work.

Next time you go to buy any rolled leatherwork and you really WANT rolled work, have a good look at it first, don't simply ask the sellers how it was manufactured, they don't seem to know as I have asked a few.

Hope you can make sense of what I am trying to explain to you.

Last edited: